ELIMINATING WASTE (MUDA)

ELIMINATING WASTE(MUDA)

In the rush to focus on revenue, many businesses forget to

consider the importance of business process and the effects of

waste. Put another way, businesses that strive to remain

streamlined and well organized have a significant advantage over

those that lack efficiency.

|

| https://bussinessideas.namanmahajan.com/2019/01/leading-top-down-innovation.html |

The idea

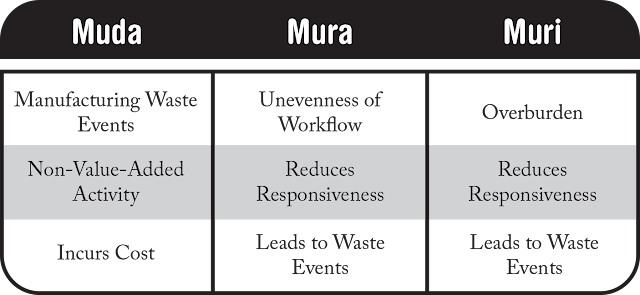

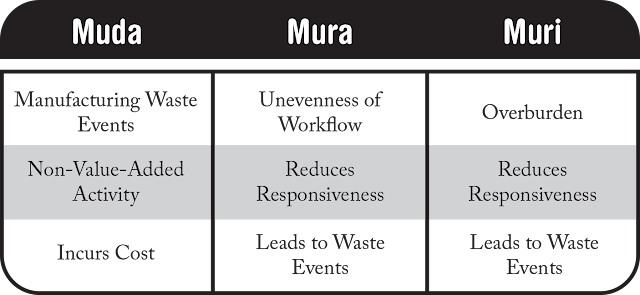

For decades, leading Japanese companies directed their cost

management efforts toward muda (waste elimination). Western

companies mirrored the success of this “Japanese Miracle” of

the 1970s and 1980s. Concepts of just in time (JIT) and waste

elimination meant that new terms, such as process analysis,

process mapping, and re-engineering, became part of the

business lexicon. The idea of process analysis is to think of business

activities as a chain of events, perhaps from the beginning of the

manufacturing process through to the end, and to break down

the chain of activities into very discrete, yet identifiable, tasks.

Following difficulties in the 1970s, senior managers at Harley Davidson visited Honda’s motorcycle facility at Marseilles, Ohio.

The difference between Honda’s facility and Harley-Davidson’s

was dramatic in terms of layout, production fl ow, efficiency, and

inventory management. The managers decided that Harley Davidson needed to introduce a business-wide JIT manufacturing

initiative called MAN (Materials As Needed). Production operations

were brought together, reducing the amount of resources required

for material handling. Harley-Davidson reduced both the amount of supplies received too early and the inventory produced too early.

This also reduced the space required for manufacturing, which

liberated additional space to increase production.

|

| https://bussinessideas.namanmahajan.com/2019/01/leading-top-down-innovation.html |

Caterpillar, a leading manufacturer of agricultural and construction

machinery, had a similar experience. During the 1980s, Caterpillar’s

cost structure was significantly higher than that of its principal

competitor—the Japanese firm Komatsu. Caterpillar concluded

that Komatsu’s “fl ow” process was more efficient than Caterpillar’s

method of moving parts and partially finished products through the

production process. It undertook a significant plant rearrangement

initiative called PWAF (Plant With a Future). The new fl ow process

reduced the distances between operations, which improved material

handling expenses, inventory levels, and cycle time to make each

product. In some cases, cycle time was reduced by as much as

80 percent.

|

| https://bussinessideas.namanmahajan.com/2019/01/leading-top-down-innovation.html |

In practice

• Analyze your production process for inefficiency and wastage. Ask

the people who run the processes how they could be improved.

This applies to service businesses as well as manufacturing and

process industries.

• Create a clear, workable plan for reducing areas of inefficiency

and replacing them with streamlined operations.

• Decide what success will look like, how it will be measured, and

when it will be assessed.

• Be cautious when introducing the new plan. Changes to any

process can have unforeseen consequences—be aware of

these possible problems and be ready to make adjustments to

compensate for them.

|

| https://bussinessideas.namanmahajan.com/2019/01/leading-top-down-innovation.html |

0 Response to "ELIMINATING WASTE (MUDA)"

Post a Comment